Philip Godfrey’s 5-Run Masonry Heater

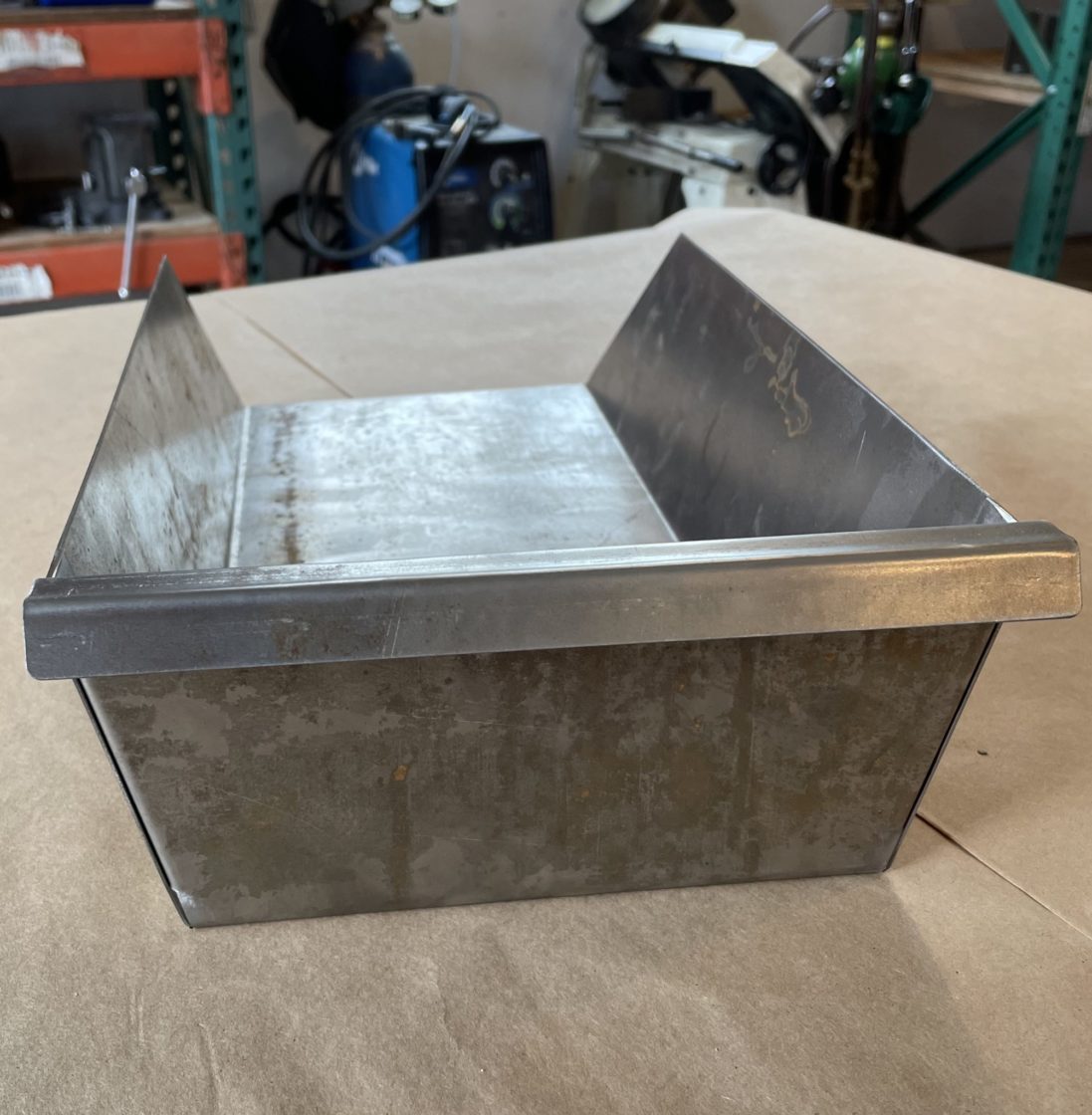

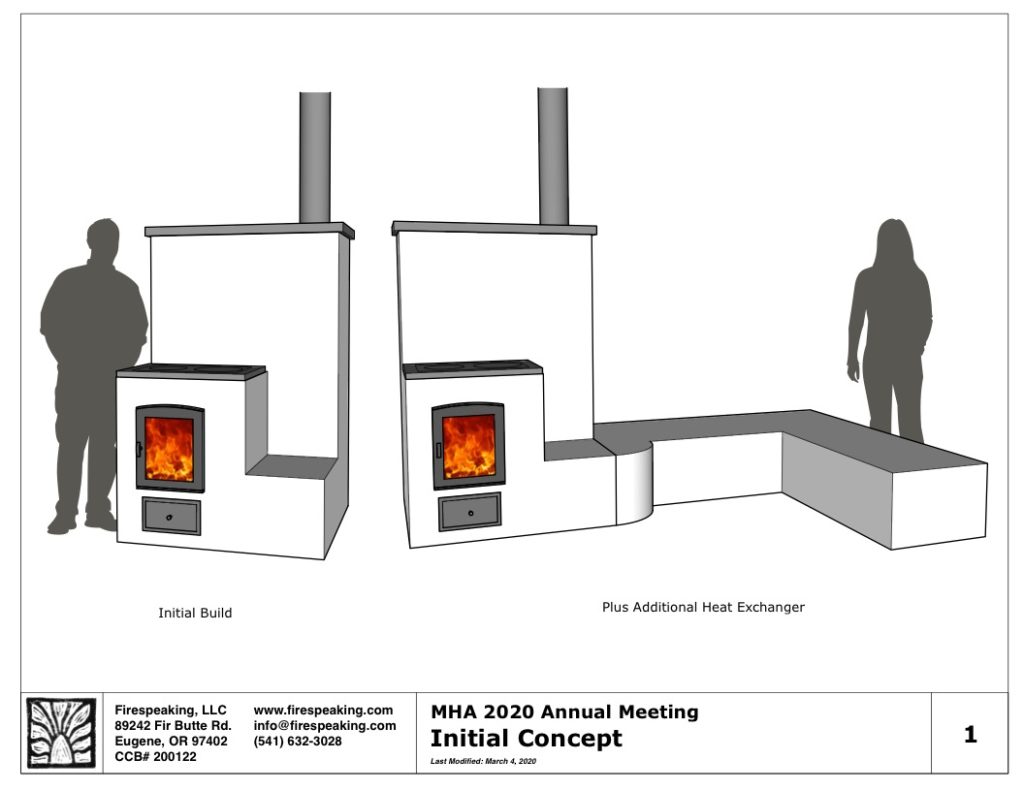

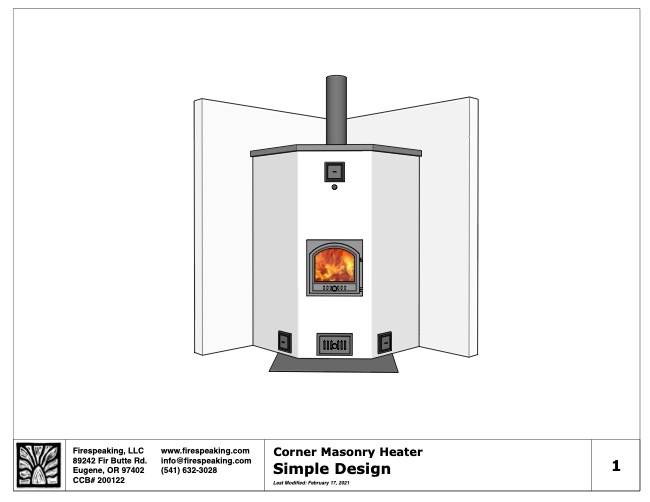

In the summer of 2023, we provided Philip Godfrey of Quebec, Canada with design services and hardware for the masonry heater he was planning to build. Philip was a DIY homeowner who had done a lot of research on masonry heaters and brought a wealth of industrial design and manufacturing experience to his project. He […]

Philip Godfrey’s 5-Run Masonry Heater Read More »