This article complements the Masonry Heater Foundation Details article by providing real-world process examples.

All framing is placed 2″ beyond the heater footprint to meet clearance requirement. Only the subfloor bridges across that clearance (since it is a membrane that can dissipate heat and is necessary practically in construction).

Although pink board was used in this build, we strongly recommend 2″ Foil Faced Rock Wool Bats for that location. The insulation doubles as formwork for the slab. The extra vertical block columns are simply to support the cement board form work for the slab above.

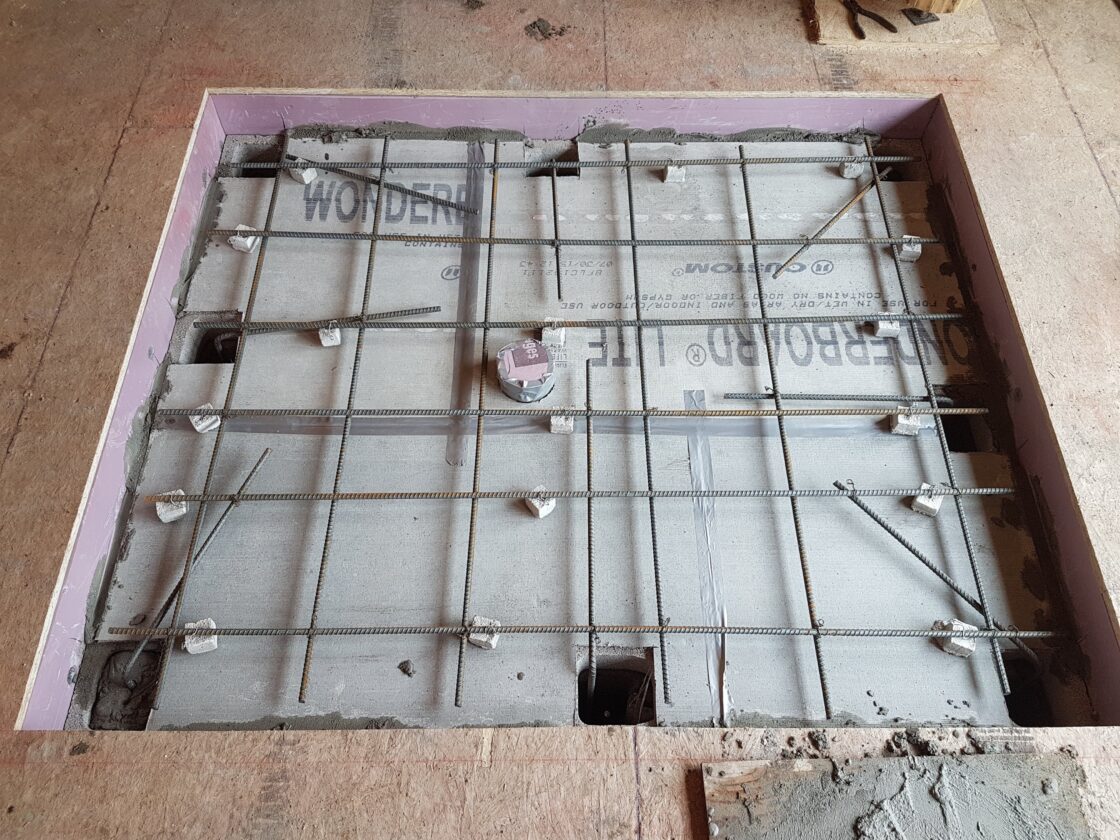

Rebar hooking from the concrete vertical posts in the block work and meeting the 12″ O.C. #4 Rebar Grid on the top slab.

Drop screed creates flat surface for additional layers.

You can see a calcium silicate board product that was used here. We far prefer the Skamol SuperIsol product, if available.

The final layer that is not pictured is the 1/2″ cement board layer to finish the foundation and prepare for the heater.

Please address any questions you have in the forum topic on this article.

Very cool! How thick is the slab?

The slab is about 4” thick.

You can see because of all the supports in the block work that the greatest span is not much more than 12”. While the slab could be thicker and have less supports, I find that it is necessary in closed foundations to temporarily support the cement board that forms the bottom of the slab to ensure it does not deform during the pour and, therefore, the spans are rarely very big.

Hi Max!

Is this for the hybrid you were recently going to build? I’m also seeing an outside air duct, yes? Will be excited to hear what you’ve learned in this build. My stove foundation is complete but I am at the materials-sourcing phase.

No, that photo sequence was for a much larger heater. I will work on linking the sequence to photos of the finished heater.